ALUMINIUM

Pre-Treatment Process for Aluminium

Preparation is a vital step in producing professional, ever lasting results in powder coating. Ensuring that the metal surface is cleaned and well-protected from corrosion and that the powder get stuck to the metal surface conveniently . This must be done for Aluminium surfaces without any hesitation .

Our pre treatment process is based on the following steps

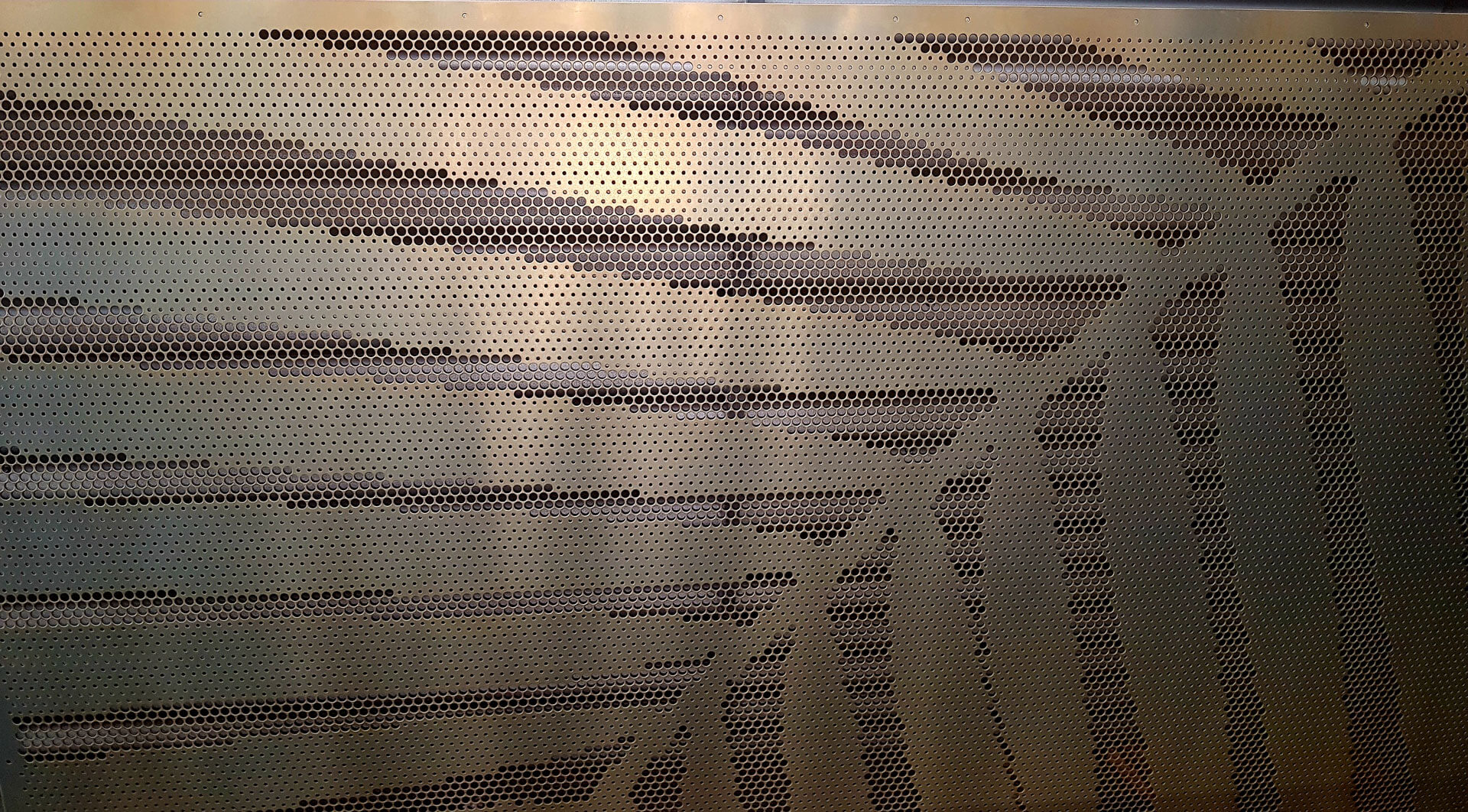

Powder Coating Process

Colors

We have access to the wide range of innumerable colors lake Dulux – Interpon –Jotun – PPG – and many more.

Packaging

We package the finished product with a conveniently attractive look.

Curabitur aliquam justo ex, ac varius sem facilisis a. Fusce ipsum enim, ultrices at ante sollicitudin, faucibus hendrenunc. Nullam tempor nulla eu imperdiet interdum.